Machine Condition Monitoring Market Size & Analysis Report By Monitoring Technique, By Offering, By Deployment Type, By Monitoring Process, By Industry and By Region – Global Opportunities and Forecast, 2020-2027

Machine Condition Monitoring Market Size & Analysis Report By Monitoring Technique (Vibration Monitoring, Thermography, Oil Analysis, Corrosion Monitoring, Ultrasound Emission, and Motor Current Analysis), By Offering (Hardware and Software), By Deployment Type (On-Premises, and Cloud), By Monitoring Process (Online Condition Monitoring and Portable Condition Monitoring), By Industry (Oil & Gas, Power Generation, Metals & Mining, Chemicals, Automotive, Aerospace & Defense, Food & Beverages, Marine, and Others), and By Region

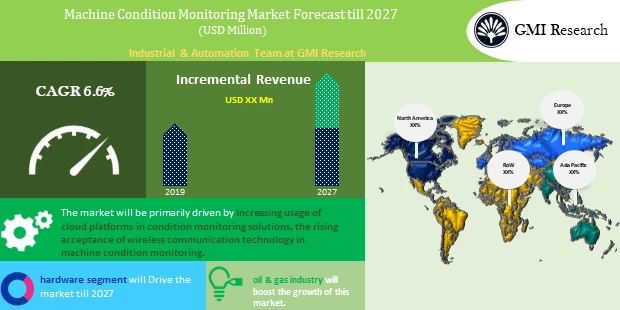

Machine Condition Monitoring Market is estimated to witness a CAGR of 6.6% during forecast period, reaching a value of USD 3,898 Million by 2027, owing to the ongoing technological advancements which include the use of wireless technologies, secure cloud computing platforms, and the integration with the Internet of Things (IoT).

To have the edge over the competition by knowing the market dynamics and current trends of “Machine Condition Monitoring Market,” request for Sample Report here

Key Drivers

The key factors propelling the growth of the Global Machine Condition Monitoring market include the increasing usage of cloud platforms in condition monitoring solutions, the rising acceptance of wireless communication technology in machine condition monitoring followed by the growing disposition towards predictive maintenance. The increasing adoption of automated condition monitoring technologies coupled with the growing penetration of smart factory will further encourage the adoption of machine condition monitoring across the globe. The growing adoption of machine condition monitoring systems as they allow proper scheduling of maintenance programs, reducing the severity of machine downtime and ensuring the equipment safety is estimated to boost the market growth. Rapid digitalization and expansion of automotive, defense, marine, food and beverage, and aerospace industries are other factors propelling the market growth. The growing awareness pertaining predictive maintenance and increasing adoption of vibration monitoring systems to compute oscillations of components have stimulated the market growth. Moreover, increasing infrastructural developments, and the growing demand for heating, ventilation and air conditioning (HVAC) systems, are expected to drive the market further.

The growing emphasis on reducing maintenance costs and minimizing the chances of unpredicted failure of the machine is promoting the manufacturers to opt for machine condition monitoring systems. The increasing adoption of machine condition monitoring across numerous industries such as oil & gas, metal & mining, automotive, aerospace & defense, and food & beverages, are further bolstering the growth of the market. According to the report published by Bloomberg, the Global Oil and Gas Analytics Market is forecast to reach USD 48130 million by the end of 2027, growing at a CAGR of 20.1% over the forecast period (2021-2027). In addition, the increasing focus on improving Safety Standards and predictive analysis and growing awareness concerned with the adopting machine condition monitoring systems, are further augmenting the market growth. The machine condition monitoring system offers remarkable benefits such as enhances safety, minimizes maintenance cost, improves operational efficiency, increases machine reliability and availability, and eliminates the chances of chronic failure, thereby increasing the life span of the machine. Moreover, the growing adoption of advanced technologies such as machine learning, big data analytics, and industrial internet of Things (IIoT) across industries will attract a large number of end-users towards the Global Machine Condition Monitoring Market. On the other hand, the limited availability of skilled resources for data analysis and the growing reliability concerns in the prediction capabilities of machine condition monitoring technology will hamper the market over the coming years.

Do you want to know more about the Research process and detailed Methodology, Request Research Methodology of this report

Monitoring Techniques Segment Analysis

Based on the monitoring techniques, the motor current analysis segment is expected to grow at a higher CAGR during the forecast period owing to the increasing adoption of current motor analysis for predicting and reducing motor failure issues such as overloading, bearing failure, unbalanced or indirect voltage, vibration or misalignment. In addition to this, the automotive industry is focussing on upgrading and automating its assembly line, which increases the demand for motor monitoring solutions as it is a significant part of the machine. Motor current analysis helps to decrease the possibility of a machine breakdown, enhance its lifespan, and reduces the overall energy consumption.

Offering Segment Analysis

Based on the offering, the hardware segment is anticipated to lead the market during the forecast period. The rising demand for hardware components used in the machine condition monitoring solutions, such as vibration sensors & analyzers, ultrasound detectors, spectrum analyzers, and corrosion probes, is the primary factor fuelling the demand of the market. These systems act as a significant component in the condition monitoring systems and provide data related to machine health in advance. The extracted information is used for predicting maintenance programs for the machines to avoid costly downtime.

Industry Segment Analysis

Based on industry, the oil & gas industry is projected to grow at a higher CAGR during the forecast period owing to the increasing emphasis on reducing operational cost and increasing profitability. The variation of oil prices across the globe is further increasing the pressure to minimize operational cost on the industry, which in turn will promote the adoption of machine condition monitoring systems to reduce operational & maintenance costs and minimize the possibility of machine downtime.

In case, any of your pain points areas are not covered in the current scope of this report, Request for Customization here

Regional Analysis

Based on the region, the Asia-pacific region is expected to grow at a higher CAGR over the forecast period due to the growing industrialization, increasing adoption of predictive maintenance tools, and rising competitive pressure to achieve operational efficiency across the Asian countries. The rising migration of production bases to Asian countries, especially in China, India, and Japan, due to the easy availability of cheap labor, is leading to the expansion of the manufacturing plants in these economies. The rapid increase in the number of manufacturing plants will drive the demand for machine condition monitoring systems in the coming years.

European Region is expected to witness a faster growth over the upcoming years, due to the emerging need to replace aged and less effective aircraft. For example, according to the Wind Europe, UK is projected to install 18 GW new wind energy capacity along with the Germany with 16GW capacity by 2025. Accelerating passenger volumes will stimulate the market growth.

Various notable players in the Machine Condition Monitoring market include General Electric, Honeywell International, Inc, Rockwell Automation, Inc., National Instruments Corporation, AB SKF, Wilcoxon Sensing Technologies, ALS, Parker-Hannifin Corporation, Schaeffler Technologies AG & Co. KG, Symphony AzimaAI, and Bruel & Kjaer.

Key Developments:

-

- In 2019, SKF acquired Presenso Ltd., an artificial intelligence (AI)-based predictive maintenance software development company. With this acquisition, SKF aims to strengthen its Rotating Equipment Performance offerings.

The Global Machine Condition Monitoring market has been segmented based on the monitoring technique, offering, deployment type, monitoring process, industry, and region. Based on the Monitoring technique, the market is segmented into Vibration Monitoring, Thermography, Oil Analysis, Corrosion Monitoring, Ultrasound Emission, and Motor Current Analysis. Based on offering, the market is segmented into hardware and software. Based on hardware, the market is segmented into Vibration Sensors, Infrared Sensors, Spectrometers, Ultrasound Detectors, Spectrum Analyzers, Corrosion Probes, and Others. Based on Vibration Sensors, the market is further segmented into Accelerometers, Proximity Probes, and, Tachometers. Based on Infrared Sensors, the market is segmented into Thermal Infrared Sensors and Quantum Infrared Sensors. Based on Spectrometers, the market is segmented into Infrared Spectrometers, Ultraviolet Spectrometers, Atomic Spectrometers, and Mass Spectrometers. Based on Ultrasound Detectors, the market is segmented into Sound Pressure Meters, Stethoscopes, and Ultrasound Leak Detectors. Based on Spectrum Analyzers, the market is segmented into Swept Spectrum Analyzers and Real-Time Spectrum Analyzers. Based on software, the market is segmented into Data Integration, Diagnostic Reporting, Order Tracking Analysis, and Parameter Calculation. Based on the deployment type, on-premise, and cloud. Based on the monitoring process, the market is segmented into Online Condition Monitoring and Portable Condition Monitoring. Based on industry, the market is segmented into Oil & Gas, Power Generation, Metal & Mining, Chemicals, Automotive, Aerospace & Defense, Food & Beverages, Marine, and Others.

For detailed scope of the “Machine Condition Monitoring Market” report request a Sample Copy of the report

Key questions answered in this research report:

-

- At what pace is the Global Machine Condition Monitoring market growing? What will be a growing trend in the future?

- What are the key drivers and restraints in the Global Machine Condition Monitoring market? What will be the impact of drivers and restraints in the future?

- What are the regional revenue and forecast breakdowns? Which are the major regional revenue pockets for growth in the Global Machine Condition Monitoring market?

- Which offering generated maximum revenues in 2019 and identify the most promising offering during the forecast period?

- What are the various industries of the Global Machine Condition Monitoring market, and how are they poised to grow?

- What companies are the major participants in this market and their business strategies, how does the competitive landscape look like?

|

Report Coverage |

Details |

| Market Revenues (2027) |

USD 3,898 Million |

| Market Base Year |

2019 |

| Market Forecast Period |

2020-2027 |

| Base Year & Forecast Units |

Revenues (USD Million) |

| Market Segment | By Monitoring Technique, By Offering, By Deployment Type, By Monitoring Process, By Industry, By Region |

| Regional Coverage | Asia Pacific, Europe, North America, and RoW |

| Companies Profiled | General Electric, Honeywell International, Inc, Rockwell Automation, Inc., National Instruments Corporation, AB SKF, Wilcoxon Sensing Technologies, ALS, Parker-Hannifin Corporation, Schaeffler Technologies AG & Co. KG, Symphony AzimaAI, Bruel & Kjaer; a total of 11 companies covered. |

| 25% Free Customization Available | We will customize this report up to 25% as a free customization to address our client’s specific requirements |

Market Segmentation

Global Machine Condition Monitoring Market by Monitoring Technique

-

- Vibration Monitoring

- Thermography

- Oil Analysis

- Corrosion Monitoring

- Ultrasound Emission

- Motor Current Analysis

Global Machine Condition Monitoring Market by Offering

-

- Hardware

- Vibration Sensors

- Accelerometers

- Proximity Probes

- Tachometers

- Infrared Sensors

- Thermal Infrared Sensors

- Quantum Infrared Sensors

- Spectrometers

- Infrared Spectrometers

- Ultraviolet Spectrometers

- Atomic Spectrometers

- Mass Spectrometers

- Ultrasound Detectors

- Sound Pressure Meters

- Stethoscopes

- Ultrasonic Leak Detectors

- Spectrum Analyzers

- Swept Spectrum Analyzers

- Real-time Spectrum Analyzers

- Corrosion Probes

- Others

- Vibration Sensors

- Software

- Data Integration

- Diagnostic Reporting

- Order Tracking Analysis

- Parameter Calculation

- Hardware

Global Machine Condition Monitoring Market by Deployment Type

-

- On-premises

- Cloud

Global Machine Condition Monitoring Market by Monitoring Process

-

- Online Condition Monitoring

- Portable Condition Monitoring

Global Machine Condition Monitoring Market by Industry

-

- Oil & Gas

- Power Generation

- Metals & Mining

- Chemicals

- Automotive

- Aerospace & Defense

- Food & Beverages

- Marine

- Others (Healthcare, Cement, Paper & Pulp, and Semiconductor & Electronics)

Global Machine Condition Monitoring Market by Region

-

- North America Machine Condition Monitoring Market

(Option 1: As a part of the free 25% customization)- North America Market by Monitoring Technique

- North America Market by Offering

- North America Market by Deployment Type

- North America Market by Monitoring Process

- North America Market by Industry

- US Market All-Up

- Canada Market All-Up

- Europe Machine Condition Monitoring Market

(Option 2: As a part of the free 25% customization)- Europe Market by Monitoring Technique

- Europe Market by Offering

- Europe Market by Deployment Type

- Europe Market by Monitoring Process

- Europe Market by Industry

- United Kingdom (UK) Market All-Up

- Germany Market All-Up

- Spain Market All-Up

- France Market All-Up

- Rest of Europe Market All-Up

- Asia-Pacific Machine Condition Monitoring Market

(Option 3: As a part of the free 25% customization)- Asia-Pacific Market by Monitoring Technique

- Asia-Pacific Market by Offering

- Asia-Pacific Market by Deployment Type

- Asia-Pacific Market by Monitoring Process

- Asia-Pacific Market by Industry

- China Market All-Up

- India Market All-Up

- Japan Market All-Up

- Rest of APAC Market All-Up

- ROW Machine Condition Monitoring Market

(Option 4: As a part of the free 25% customization)- RoW Market by Monitoring Technique

- RoW Market by Offering

- RoW Market by Deployment Type

- RoW Market by Monitoring Process

- RoW Market by Industry

- Brazil Market All-Up

- South Africa Market

- Saudi Arabia Market

- UAE Market All-Up

- Rest of world (remaining countries of the LAMEA region) Market All-Up

- North America Machine Condition Monitoring Market

Global Machine Condition Monitoring Market Leading Players (Option 5: As a part of the free 25% customization – Profiles of 5 Additional Companies of your Choice)

-

- General Electric

- Honeywell International, Inc

- Rockwell Automation, Inc.

- National Instruments Corporation

- AB SKF

- Wilcoxon Sensing Technologies

- ALS

- Parker-Hannifin Corporation

- Schaeffler Technologies AG & Co. KG

- Symphony AzimaAI

- Bruel & Kjaer

Frequently Asked Question About This Report

Machine Condition Monitoring Market [UP708A-00-0620]

The Asia-pacific region is expected to grow at a higher CAGR over the forecast period due to the growing industrialization, increasing adoption of predictive maintenance tools, and rising competitive pressure to achieve operational efficiency across the Asian countries.

The growth rate of Machine Condition Monitoring Market during 2020-2027 is 6.6%.

The oil & gas industry is projected to grow at a higher CAGR during the forecast period owing to the increasing emphasis on reducing operational cost and increasing profitability.

The Various notable players in this Machine Condition Monitoring market include General Electric, Honeywell International, Inc, Rockwell Automation, Inc., National Instruments Corporation, AB SKF, Wilcoxon Sensing Technologies, ALS, Parker-Hannifin Corporation, Schaeffler Technologies AG & Co. KG, Symphony AzimaAI, and Bruel & Kjaer.

- Published Date: Jun-2020

- Report Format: Excel/PPT

- Report Code: UP708A-00-0620

Licensing Options

Single-User License:

The report is used by the purchaser (One Individual) only

Multi-User License:Report is shared with maximum 5 users (employees) including the purchaser of the purchasing corporation only

Corporate License:

Report is shared with unlimited user (employees) of the purchasing corporation only

The report is used by the purchaser (One Individual) only

Multi-User License:Report is shared with maximum 5 users (employees) including the purchaser of the purchasing corporation only

Corporate License:

Report is shared with unlimited user (employees) of the purchasing corporation only

Machine Condition Monitoring Market Size & Analysis Report By Monitoring Technique, By Offering, By Deployment Type, By Monitoring Process, By Industry and By Region – Global Opportunities and Forecast, 2020-2027

$ 4,499.00 – $ 6,649.00

Why GMI Research