Composite Rollers Market by Fiber Type (Glass, Carbon and Others), By Resin Type (Thermoset and Thermoplastic), By End-Use Industry (Textile, Mining, Film & Foil Processing, Pulp & Paper and Others) and By Geography – Opportunities & Forecast, 2022-2029

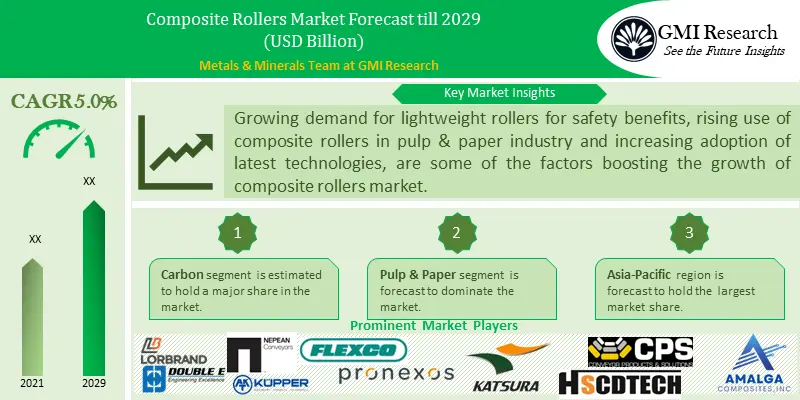

GMI Research analysis indicates that the Composite Rollers Market is slated to register a CAGR of 5.0% over the forecast period, till 2029 attributed to surge in the demand for lightweight rollers worldwide.

Composite rollers encompass of the principal business of several industries. These rollers are made by using raw material such as fibers, resins, prepreg fabrics and two technologies. The two technologies that are involved for this purpose are filament winding and wrapping. The constant development in the industrial machineries is linked to lightweight and lower consumption of energy. Such an evolution led to the increased application of composite material in several sectors.

To have an edge over the competition by knowing the market dynamics and current trends of “Composite Rollers Market” request for Sample Report here

Primary Composite Rollers Market Drivers

Composite rollers market is majorly driven by increasing demand for lightweight and durable rollers to achieve operational efficiency, growing adoption of advanced technologies, and increasing use of composite rollers in pulp & paper industry. In addition, rising mining and exploration activities where such rollers find application in specific areas in mines, is driving the growth of composite rollers market. Composite rollers are increasingly used in mining applications for conveying bulk materials. Since composite rollers are lightweight and is environment friendly, its usage in the mining industry is expected to increase in the coming years.

Composite rollers offer resistivity to corrosion, increased strength, lightweight, higher tension along with various safety and operational benefits, led to its increased popularity in several industries, which in turn is propelling the growth of composite rollers market. Rising demand for the carbon fiber composite rollers in paper and pulp industries and also in textile industries is leading to the growth of market. Such rollers offer reduced vibration and noise, low inertia, less electricity consumption, longer life and durability in even the toughest application when compared to other rollers is boosting the demand for composite rollers. The factors hindering the growth of global composite rollers market include the high cost of raw material and also high fabrication and assembly costs and greater difficulty in repairing when compared to metallic structures.

Do you want to know more about the Research process and detailed Methodology, Request Research Methodology of this report

Based on Fiber Type, Carbon segment is projected to capture a significant share in the market.

Carbon fiber based composite rollers are gaining traction in the market as these rollers are lightweight and offers increased strength and performance. Furthermore, growing demand for these composite rollers from film and food processing, pulp and paper and textile industry, is accelerating the segment’s growth.

Resin Type: Segment Analysis

Thermoplastic composites find its application in composite roller manufacturing. Enterprises are preferring to use these types of composite rollers as it offers excellent chemical resistance and increased dimensional stability.

Based on End-Use, Pulp & Paper segment is estimated to hold a major share in the Composite Rollers Market.

In the pulp and paper industry, composite rollers find its application primarily in printing roller and guide rollers. Composite rollers are increasingly used in pulp and paper mills as it offers resistance to corrosion, temperature and chemicals.

In case, any of your pain points areas are not covered in the current scope of this report, Request for Customization here

Based on Region, Asia-Pacific region is estimated to dominate the market.

Asia-Pacific composite rollers market is driven by presence of the leading iron ore and mineral producing countries like Australia and China, growing flexible packaging market and mining industry. Due to increasing mining activities in Australia, it has emerged as the largest iron ore mining country worldwide. As per recent estimates, the mine production of usable iron ore in the country was estimated to be 880 million metric tons in 2022. Further the Australian government is planning to provide loan worth A$2 billion to support companies who are operating in the critical mineral industry, such initiatives are expected to create lucrative growth opportunities for the composite rollers market in the Asia-Pacific region.

Top Market Players

Various notable players operating in the global composite rollers market are Lorbrand Composites, NEPEAN Conveyors, Double E Company LLC, Artur Kupper GmbH & Co. KG, Flexible Steel Lacing Company, Pronexos, Kastura Roller Manufacturing Corporation Ltd., Conveyor Products & Solutions, Beijing Haosheng Transmission Technology Co. Ltd., and Amalga Composites Inc., among others.

Key Developments:

-

- In March 2021, Pronoexos launched a new range of wear resistant composite coatings Tonex, which are designed for CFRP rollers. These composite coatings will help users to meet their printing and packaging requirements.

- In March 2019, Pronexos, a major manufacturer of high-quality carbon fibre products based out of Netherlands parented with Apex International, to supply advanced carbon fiber rollers to their customers.

- In 2017, NEPEAN Conveyors announced that it has acquired Sandvik’s conveyor system business and international conveyor components business. This acquisition helped NEPEAN conveyors to strengthen its position in the composite rollers market.

Segments Covered in the Report

The global composite rollers market has been segmented on the basis of fiber type, resin type, end-use industry and key geographies. Based on fiber type, the market is categorized into Glass, Carbon and Others. Based on resin type, the market is categorized into Thermoset and Thermoplastic. Based on end-use industry, the market is categorized into Textile, Mining, Film & Foil Processing, Pulp & Paper and Others.

For detailed scope of the “Composite Rollers Market” report request a Sample Copy of the report

|

Report Coverage |

Details |

| Market Revenues (2021) |

USD Million |

| Market Base Year |

2021 |

| Market Forecast Period |

2022-2029 |

| Base Year & Forecast Units |

Revenues (USD Million) |

| Market Segment | By Fiber Type, By Resin Type, By End-Use Industry, By Region |

| Regional Coverage | Asia Pacific, Europe, North America, and RoW |

| Companies Profiled | Lorbrand Composites, NEPEAN Conveyors, Double E Company LLC, Artur Kupper GmbH & Co. KG, Flexible Steel Lacing Company, Pronexos, Kastura Roller Manufacturing Corporation Ltd., Conveyor Products & Solutions, Beijing Haosheng Transmission Technology Co. Ltd., and Amalga Composites Inc., among others; a total of 10 companies covered. |

| 25% Free Customization Available | We will customize this report up to 25% as a free customization to address our client’s specific requirements |

Market Segmentation

Global Composite Rollers Market by Fiber Type

-

- Glass

- Carbon

- Others

Global Composite Rollers Market by Resin Type

-

- Thermoset

- Thermoplastic

Global Composite Rollers Market by End-Use Industry

-

- Textile

- Mining

- Film & Foil Processing

- Pulp & Paper

- Others

Global Composite Rollers Market by Region

-

- North America Composite Rollers Market (Option 1: As a part of the free 25% customization)

- By Fiber Type

- By Resin Type

- By End-Use Industry

- US Market All- Up

- Canada Market All- Up

- Mexico Market All- Up

- Europe Composite Rollers Market (Option 2: As a part of the free 25% customization)

- By Fiber Type

- By Resin Type

- By End-Use Industry

- UK Market All- Up

- Germany Market All- Up

- Spain Market All- Up

- Rest of Europe Market All- Up

- Asia-Pacific Composite Rollers Market (Option 3: As a part of the free 25% customization)

- By Fiber Type

- By Resin Type

- By End-Use Industry

- China Market All- Up

- Australia Market All- Up

- India Market All- Up

- Rest of APAC Market All- Up

- ROW Composite Rollers Market (Option 4: As a part of the free 25% customization)

- By Fiber Type

- By Resin Type

- By End-Use Industry

- Brazil Market All- Up

- South Africa Market All- Up

- GCC countries Market All- Up

- Rest of world (remaining countries of the LAMEA region) Market All- Up

- North America Composite Rollers Market (Option 1: As a part of the free 25% customization)

Leading market players

-

- Lorbrand Composites

- NEPEAN Conveyors

- Double E Company LLC

- Artur Kupper GmbH & Co. KG

- Flexible Steel Lacing Company

- Pronexos

- Kastura Roller Manufacturing Corporation Ltd.

- Conveyor Products & Solutions

- Beijing Haosheng Transmission Technology Co. Ltd.

- Amalga Composites, Inc.

Frequently Asked Question About This Report

Composite Rollers Market [UP210A-00-1219]

Composite rollers market is expected to grow at a CAGR of 5.0% during the forecast period 2022-2029.

Carbon segment is projected to hold a major share in the market.

Asia-Pacific region is estimated to capture the largest market share.

Major companies operating in the composite rollers market are Amalga Composites Inc., Artur Kupper GmbH & Co. KG, Flexible Steel Lacing Company, Pronexos, Lorbrand Composites, NEPEAN Conveyors, Double E Company LLC, Kastura Roller Manufacturing Corporation Ltd., Conveyor Products & Solutions, and Beijing Haosheng Transmission Technology Co. Ltd., among others.

- Published Date: Nov-2021

- Report Format: Excel/PPT

- Report Code: UP210A-00-1219

Licensing Options

Single-User License:

The report is used by the purchaser (One Individual) only

Multi-User License:Report is shared with maximum 5 users (employees) including the purchaser of the purchasing corporation only

Corporate License:

Report is shared with unlimited user (employees) of the purchasing corporation only

The report is used by the purchaser (One Individual) only

Multi-User License:Report is shared with maximum 5 users (employees) including the purchaser of the purchasing corporation only

Corporate License:

Report is shared with unlimited user (employees) of the purchasing corporation only

Composite Rollers Market by Fiber Type (Glass, Carbon and Others), By Resin Type (Thermoset and Thermoplastic), By End-Use Industry (Textile, Mining, Film & Foil Processing, Pulp & Paper and Others) and By Geography – Opportunities & Forecast, 2022-2029

$ 4,499.00 – $ 6,649.00

Why GMI Research